Sterile medical equipment clean room part set requirements

Summary:

Dongguan

City, Dongguan City for the mechanical and electrical purification of

sterile medical equipment clean room clean room (district) level of the

principle of setting, and medical equipment plant on the work,

production and plant environmental requirements, the overall layout of

the rationality and clean production area production process and Static pressure and other requirements.

Key words:

Medical equipment clean room clean room clean area environmental

requirements layout production area cleanliness level set principle

Requirements for working environment

If it is possible to adversely affect the quality of the product, the

working environment conditions should be made quantitative or

qualitative provisions

Including from the purchase of raw materials (from the delivery or

transport); to storage, production and processing, monitoring and

measurement, as well as finished product storage, transportation, etc.,

until the product delivered to customers so far.

Develop environmental conditions to control program documentation or

work instructions to monitor and control environmental conditions

If the environmental condition control is a special process, the process should also be confirmed.

Production environment requirements

Site selection should be considered

The surrounding natural environment and health conditions are good, at

least there is no air or water pollution sources, should be away from

the traffic arteries, freight yard and so on.

Plant environmental requirements

Plant ground, the road should not be easy to dust. It is advisable to reduce the terrestrial area or control dust by greening. Garbage, idle items, etc. should not be open storage, etc., in short,

the factory environment should not be sterile medical equipment

production pollution.

The overall layout of the plant is reasonable

Not on the sterile medical equipment production area, especially the

clean area has a negative impact; flow, logistics should be separated.

On the new, expansion of the sterile medical equipment manufacturing

enterprises, the proposed by the pharmaceutical industry clean factory

design qualification of the unit design.

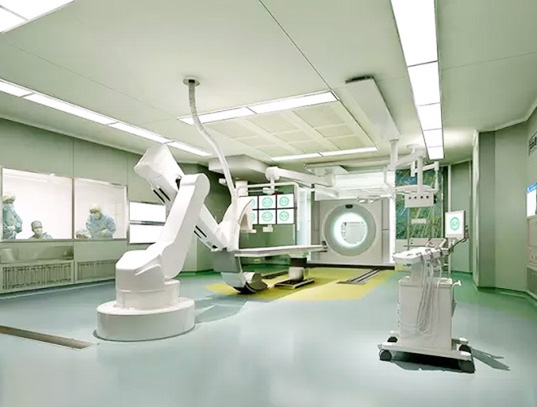

Clean production area

Determine the process of production in the clean room (area)

Analyze, identify and identify processes that are produced in a clean

room (area) and identify them in the relevant technology or process

documentation.

Cleanliness (area) cleanliness level to meet the "set principle" requirements.

"Set the principle" can not cover or not a single purpose of the

product, the environmental cleanliness level to the product similar to

the same use or similar to rely on the principle should be high should

not be low on the low must be verified.

Clean room (area) static pressure requirements

Different levels of clean room (area) between ≥ 5Pa, clean room (area) and outdoor ≥ 10Pa

There should be differential pressure indicating device.

The same clean room (area) between the pressure gradient is

reasonable: the relatively high demand for a higher pressure, if the two

processes may have a certain impact, fear of the higher impact.

Clean room (area) cleanliness level set principle

First, the use of pollution to minimize the production technology to

ensure that medical devices are not contaminated or can effectively

eliminate pollution.

Advocate for technological progress, it is recommended to use advanced production technology.

Advanced production technology, equipment, tooling and facilities.

In the process of product formation to minimize the human factors, the

maximum extent that the product is not exposed to the operating

environment, as far as possible to avoid direct contact with the

product.

Second,

the implantation and intervention into the blood vessels and the need

for a hundred times in the local 100-class clean area for follow-up

processing (such as filling letters, etc.) equipment, not cleaning parts

processing, cleaning, assembly, And its sealing, not less than 10000 level.

Implanted into the blood or the heart of the device, such as: vascular

stent, heart valve, artificial blood vessels, pacing electrodes,

artificial arteriovenous fistula, vascular grafts, in vivo drug release

catheters and ventricular assist devices.

Intervention into the blood of the device, such as: a variety of

intravascular catheter (such as central venous catheter), stent delivery

system.

Third,

implanted into human tissue, with blood, bone or non-natural cavity

directly or indirectly contact the device, (not cleaning) parts

processing, the end of cleaning, assembly, the initial packaging and

sealing, not less than 100000 level.

Devices implanted into human tissue, such as pacemakers, drug delivery

devices, neuromuscular sensors and stimulators, artificial tendons,

breast implants, artificial laryngeal, subperiosteal implants and

ligaments.

Instruments that are in direct contact with blood, such as plasma separators, blood filters, and the like.

And

the blood on a certain point of contact, as a pipeline to the vascular

system input device, which is indirectly through the liquid or blood and

blood contact with the human body, such as: one-time use of infusion,

one-time use of blood transfusion, one-time use of intravenous infusion Needles, extenders, transfer devices and so on.

Mainly in contact with bone equipment, such as: orthopedic nails,

orthopedic panels, artificial joints, bone prostheses, artificial bone,

bone cement and bone equipment.

Fourth, with the body damage the surface and mucosal contact

equipment, (not cleaning) parts of the processing, the end of fine

washing, assembly, the initial packaging and sealing, not less than

300000 level.

Contact with the injured surface (wound or other damage to the body

surface) contact equipment, such as: ulcers, burns, granulation tissue

dressings or treatment equipment, "Band-Aid" and so on.

Contact with the mucous membrane or natural cavity device, such as:

sterile catheter, sterile tracheal intubation, which is characterized by

no puncture or incision into the body of the device.

Fifth, the initial packaging materials production environment requirements

And the use of sterile medical equipment in direct contact with the

surface, do not clean the use of the initial packaging materials, should

follow the same degree of cleanliness of the production environment and

the principle of the original packaging materials to meet the quality

of packaging sterile medical equipment requirements.

Such as intravascular catheters, artificial breasts, catheters and other primary packaging materials. If the initial packaging material is not in direct contact with the

surface of the use of sterile medical equipment, not less than 300000

level.

Such as disposable infusion sets, disposable blood transfusions, disposable syndromes such as sterile syringes.

6, for the requirements or aseptic processing filling, at 10 000 under the local 100 clean area.

Such as vascular support of the pressure grip, Tu drug;

Blood bag production of anticoagulants, maintenance liquid filling;

Liquid products for aseptic preparation and filling;

As well as sterile treatment, transport and packaging of solid products that can not be finalized in their containers.

7, clean work clothes cleaning, drying and wearing clean clothes

service room, special station equipment cleaning and disinfection of the

end of the area of air cleanliness level can be lower than the

production area of a level.

Disinfection of sterile work clothes can be clean in 100000 clean

areas, but after finishing the sterilization, storage should be 10,000

clean room (area).

Clean uniforms cleaning, finishing the minimum level of 300,000 clean areas.